When choosing between silicone and acrylic, it's important to consider their unique properties and applications.

1. Material Composition

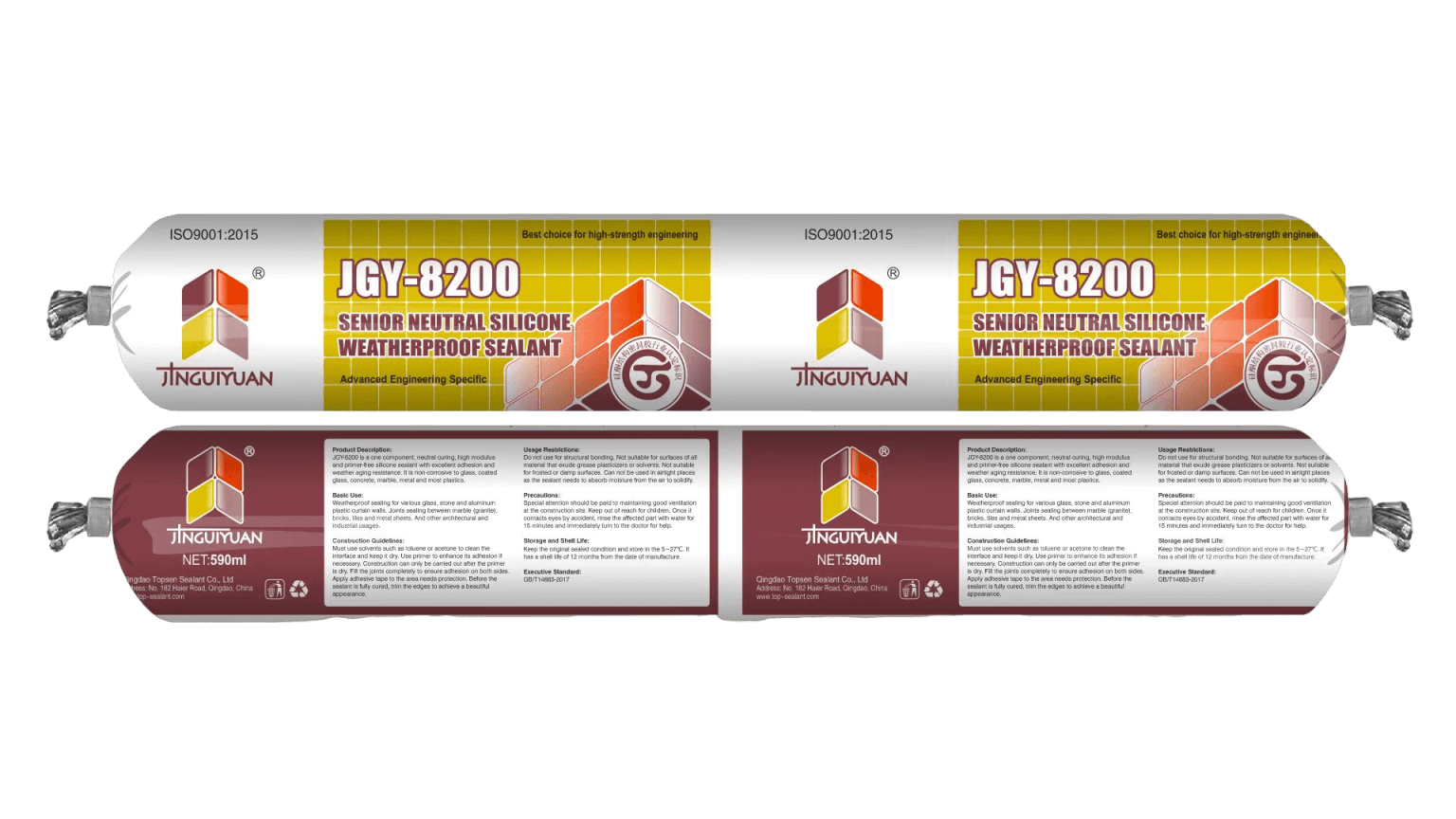

- Silicone is a flexible polymer made from silicon, oxygen, and other elements, known for its durability and versatility.

- Acrylic (PMMA) is a rigid, transparent polymer, often used in applications requiring clarity.

2. Flexibility

- Silicone is highly elastic, ideal for sealing joints and areas that experience movement.

- Acrylic is rigid and less flexible, making it more prone to cracking under pressure.

3. Temperature Resistance

- Silicone performs well in extreme temperatures (-60°C to 200°C), making it suitable for both hot and cold environments.

- Acrylic has a lower tolerance for heat and may deform or crack at higher temperatures.

4. Weather and UV Resistance

- Silicone is highly resistant to UV, weather, and ozone, making it perfect for outdoor use.

- Acrylic can discolor and degrade over time when exposed to UV radiation.

5. Adhesion

- Silicone adheres well to many materials like glass and metal, making it great for sealing.

- Acrylic is best used for bonding in structural applications but is less effective in areas with movement or extreme conditions.

6. Applications

- Silicone is used in construction, automotive, medical devices, and waterproofing.

- Acrylic is ideal for signage, displays, windows, and transparent enclosures.

7. Cost and Durability

- Silicone is more expensive but offers superior durability in harsh conditions.

- Acrylic is cost-effective but may require more maintenance in extreme environments.

Conclusion

Choose silicone for flexibility, durability, and extreme conditions, and acrylic for transparency, rigidity, and budget-friendly projects.