Silicone sealants play a crucial role in construction, industrial applications, and household repairs. They provide strong adhesion, flexibility, and durability, making them essential for sealing gaps, waterproofing, and protecting surfaces. Understanding key aspects of silicone sealants can help you choose and use them correctly. Here are ten essential knowledge points you need to know.

1. Silicone Sealants Are Highly Flexible

Unlike traditional sealants, silicone remains flexible even after curing. This makes it ideal for sealing joints and materials that experience expansion and contraction due to temperature changes or movement.

2. There Are Two Main Types: Acetic-Cure and Neutral-Cure

- Acetic-Cure Silicone (also called acid-cure) releases acetic acid when curing and has a strong vinegar-like smell. It provides excellent adhesion to glass, ceramics, and non-porous surfaces but can corrode metals and sensitive materials like marble.

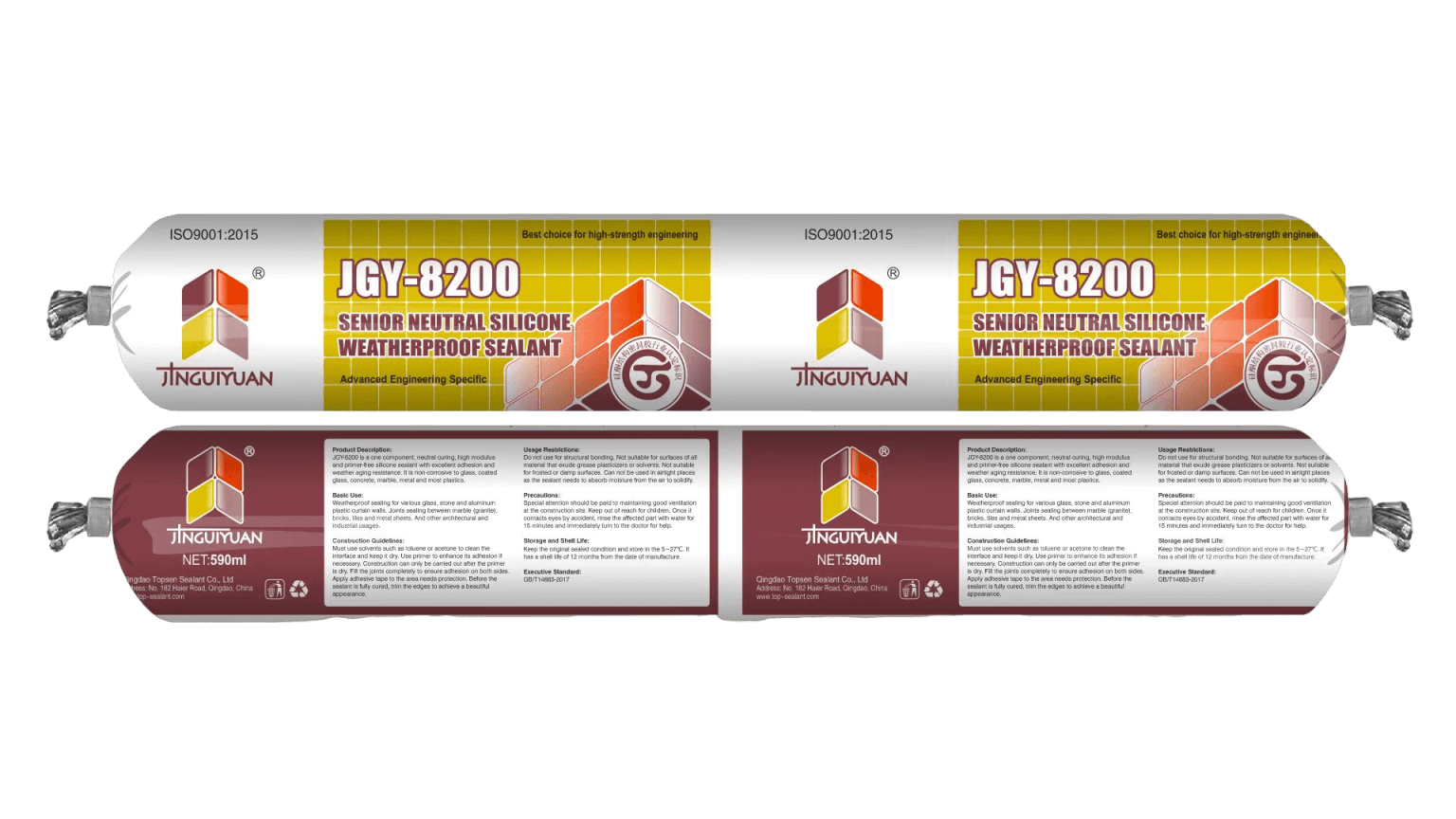

- Neutral-Cure Silicone is non-corrosive and safe for most building materials, including metals, natural stone, and plastics. It takes longer to cure but is ideal for applications requiring strong adhesion without material damage.

3. Silicone Sealants Are Waterproof and Weather-Resistant

Silicone sealants create a waterproof barrier, making them perfect for bathrooms, kitchens, windows, and outdoor applications. Many silicone products, like Topsen 8800, are designed to withstand UV rays, rain, and extreme weather conditions.

4. Not All Silicone Sealants Are Suitable for Structural Bonding

While some silicone sealants, like Topsen 8800, are formulated for structural glazing, others are only suitable for general sealing. Always check the product specifications before use, as standard sealants cannot bear heavy loads.

5. Acidic Silicone Can Corrode Certain Metals

Acetic-cure silicone can react with copper, brass, galvanized steel, and some coated glasses, leading to corrosion. When working with these materials, neutral-cure silicone, such as Topsen 793, is a safer choice.

6. Some Silicone Sealants Offer Mold and Mildew Resistance

For areas exposed to moisture, such as kitchens and bathrooms, using a mildew-resistant silicone sealant is essential. Products like Topsen 793 prevent mold growth, ensuring long-term cleanliness and hygiene.

7. Proper Surface Preparation Is Crucial for Strong Adhesion

Before applying silicone sealant:

- Clean the surface thoroughly to remove dust, grease, and moisture.

- Ensure the area is dry since silicone does not adhere well to wet or frosty surfaces.

- Use a primer if necessary to enhance adhesion on difficult substrates.

8. Silicone Sealants Require Curing Time

Silicone does not dry instantly. The curing process depends on factors like humidity, temperature, and the thickness of the applied sealant. Most silicone sealants take 24 to 48 hours to fully cure, while structural-grade silicones may take longer.

9. Silicone Cannot Be Painted Over

Unlike acrylic sealants, paint does not adhere well to silicone. If painting is necessary, use a paintable sealant or apply masking techniques before sealing. Alternatively, choose a colored silicone that matches the surface.

10. Different Grades Exist for Specific Applications

Silicone sealants are formulated for different uses, including:

- General-purpose sealants like Topsen 517, used for interior decoration.

- Weatherproofing sealants like Topsen 680, designed for small glass curtain walls and aluminum plates.

- Structural-grade silicones like Topsen 8800, suitable for high-performance glass curtain walls.

- Specialized sealants like Topsen 119 Fireproof Sealant, used for fire-rated applications.

Conclusion

Understanding these 10 key knowledge points about silicone sealants can help you select the right product for your needs and ensure proper application. Whether for construction, waterproofing, or industrial sealing, choosing the correct silicone sealant enhances durability, safety, and performance.