The key difference between weatherproof sealants and structural sealants lies in their intended applications and performance characteristics.

-

Weatherproof Sealants:

- Primary Use: Designed mainly to prevent water, air, dust, and debris from penetrating the building’s exterior. They’re generally used in applications like sealing around windows, doors, and curtain walls.

- Features: Weatherproof sealants are typically formulated to withstand exposure to various weather conditions, including UV rays, rain, wind, and temperature fluctuations. They offer good adhesion to a variety of materials but aren't necessarily intended to bear heavy loads.

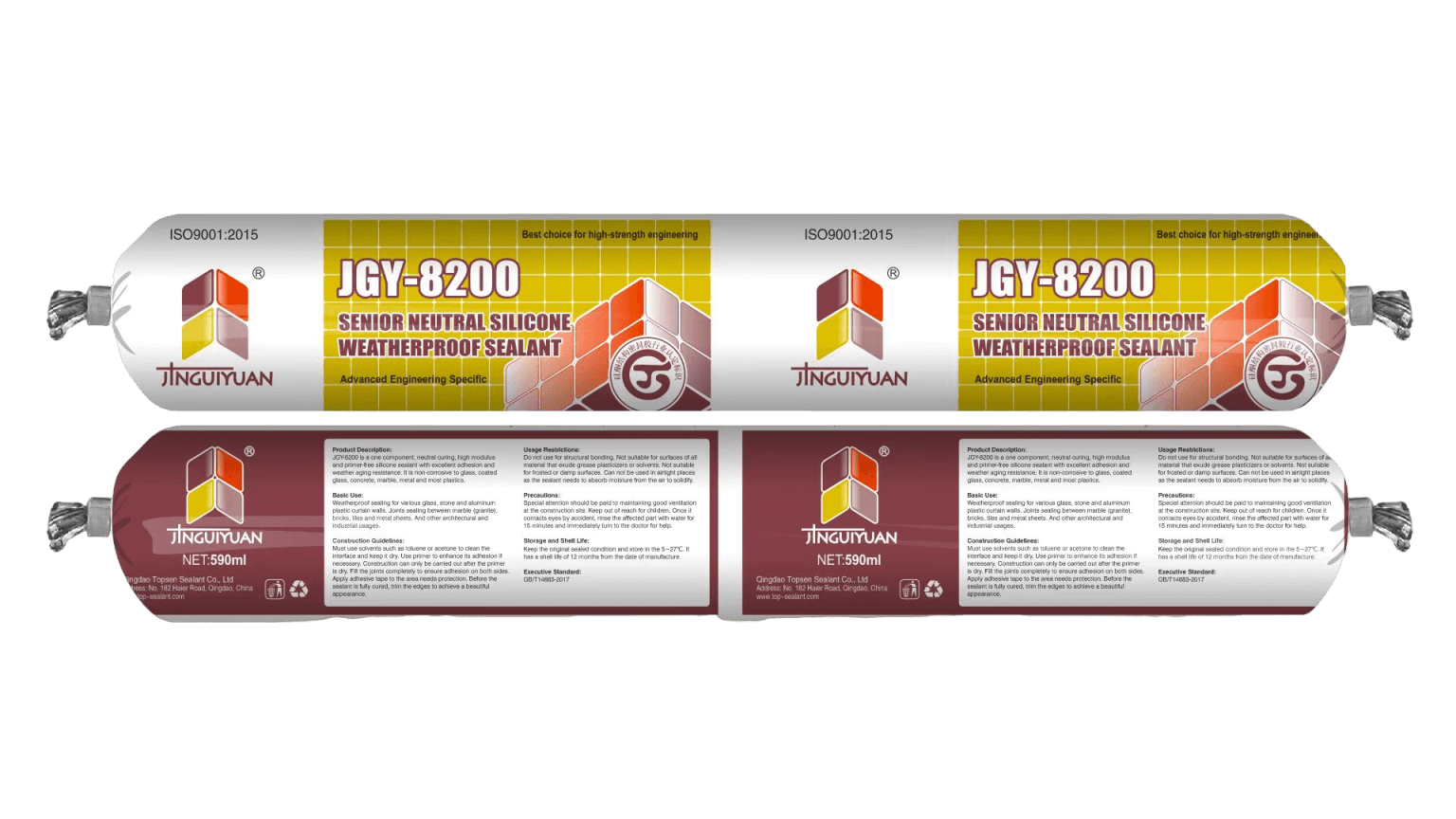

- Examples: Topsen 8200 Curtain Wall Silicone Sealant (for facade construction) or Topsen 680 Silicone Sealant (for smaller glass curtain walls and aluminum plates).

-

Structural Sealants:

- Primary Use: Used in the structural bonding of materials, typically in applications where the sealant is required to hold components together as part of the building’s load-bearing system. For instance, they’re used in the assembly of glass curtain walls or to bond glass to metal.

- Features: Structural sealants offer high strength and load-bearing capabilities, meaning they can handle significant mechanical stresses. They also need to perform well under long-term exposure to environmental factors like UV rays, moisture, and temperature extremes.

- Examples: Topsen 8800 Silicone Structural Sealant (ideal for structural bonding in glass curtain walls and other heavy-duty applications).

In short, while weatherproof sealants focus on protecting against the elements, structural sealants are engineered to provide durability and support for structural bonding in demanding applications.